Elektrotechnik Weber wins sustainability award

Sustainability is not a buzzword for us, we have been living it since the company was founded in 2014! From the very beginning, we have supported other companies in the electronics industry with our knowledge and experience in finding errors, analyzing causes and saving assemblies instead of scrapping them.

This commitment of ours has now been extensively recognised: District President Franz Löffler awarded Ilona and Freddy Weber the first sustainability prize in the region of Oberpfalz.

Welcome

to Elektrotechnik Weber

You have just found the flexible problem solver in electronics manufacturing!

Patterns and small series. Washing and cleaning. X-ray and quality assurance. Repairs and rework. Selective soldering. Are you facing a different challenge? Qualify manufacturing processes on unusual substrates? Repair Gold Contacts? Add 0201 components?

Ask us. So far, we've got every manufacturing problem in electronics under control!

Our standard services

X-ray & quality assurance

- BGA soldered optimally?

- Soldering joints bubble-free?

- Potted components damaged?

We provide distinctness, prepare the related reports and give indications how to avoid rejects in the future!

Washing & cleaning

The easiest way to avoid corrosion-related disturbances, such as gaps, signal distortions, leakage currents or electrochemical migration.

Be sure, we match the cleaning process to your assembly!

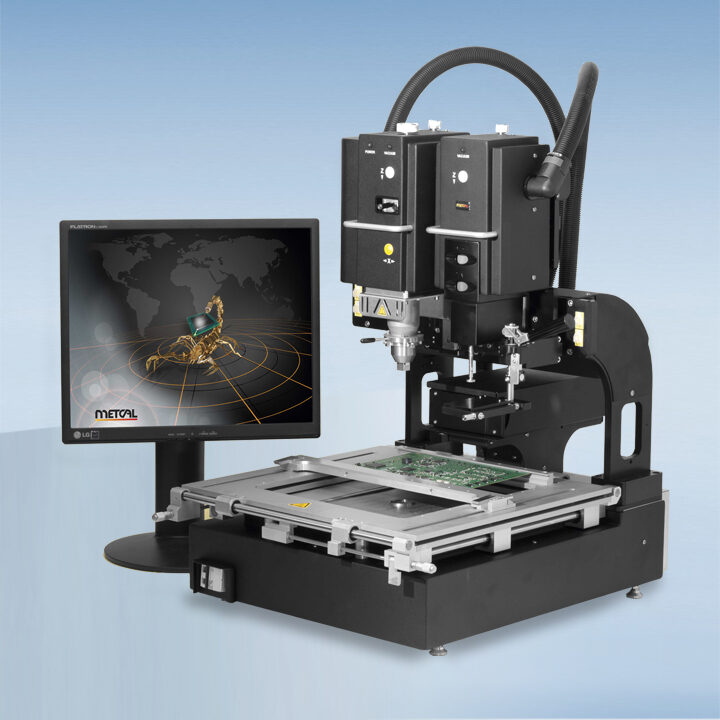

Repairs & Rework

- Wrong component/BGA soldered?

- Assembly of "forgotten" SMD/THT components

- Hand soldering and selective soldering

- Samples and small series

- Repair of gold contacts and gold surfaces

We save your assembly. If it has to be, even overnight!

The flexible problem solver

in electronics production

Does not work, does not exist. Or "des mou scho gai" as we say here in the Upper Palatinate. Our customers know: this is not an empty promise. After all, electronics production has been at home here in Zandt for over 50 years.

Admittedly, we are a bit proud of our self-developed thermal process for the repair of gold contacts and gold surfaces. Solder splashes and contamination by tin can be removed without residue. Of course, without affecting or even deforming the nickel layer (no grooves). Subsequently, the area is electrolytically gold plated. And best of all, the process is IPC compliant!

The proverbial soft water of the forested mountains is not only suitable for brewing excellent beers. With the right cleaning chemistry, there simply will not be any residue left on your assembly. Take the test!

Just took your eye off the ball for a few seconds - and now 120 boards carry the wrong BGA. We swap them. Maybe others can do that, too. But we X-ray the PCBs afterwards and prove the perfect soldering individually.

Our service for you

We are always at your disposal for your individual requirements and questions.

Fast

Flexible

Solution-oriented

Hand in hand

even in these times!

Our knowledge protects you against production problems - our hand disinfector against smear infections.

Whatever their name may be. Because preventing problems in the first place - or solving them correctly - is our business. After we are in contact and you place your first order with us, I will send you our hand disinfector immediately.

Would you like to know more about it?

- Send an email to info@etech-weber.de

- Call us: +49 99 44 30 46 06

- Use our Contact-Form

- Or contact me via XING

We are here for you. Whenever you need us. Flexibility and speed are our DNA!